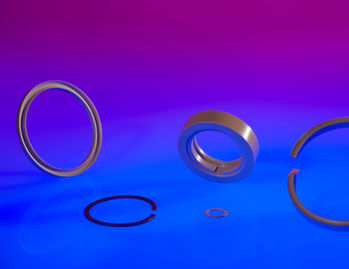

PEEK

Machined Parts Quote

PEEK (Polyether ether ketone) is a semi-crystalline thermosetting plastic commonly used for industrial and technology applications, in harsh environments, and where a strong material is needed to be resistant to pressure and weight. PEEK is known to exhibit similar strength qualities as some metals, even being compared to steel.

PEEK's physical properties make it one of the superior plastics available today. Its melting point is 662' F. Additionally, it has been tested as having a viable utility at up to 500' F. Because of its resilience to heat, PEEK is classified as a plastic that is not susceptible to Thermal Degradation. Not only does this mean that PEEK will not melt or deform in most high temperature environments, but also it will not relax or creep when exposed to heat. PEEK also has excellent dielectric properties and a low coefficient of friction. It is an excellent performer in applications which require chemical, mechanical, and water resistance as well.

PEEK is becoming increasingly popular in industrial manufacturing as it is gaining more attention for its wide range of uses. Popular industries that utilize PEEK parts include Medical/Pharmaceutical, Oil & Gas, Semiconductor and CPB manufacturing, Aerospace, and Fluid Control. Virgin (or Natural) PEEK is offered usually in either extruded or injection molded forms as stock. Additionally filled grades of PEEK are available to offer more unique physical properties. Accumatics offers both Carbon Filled and Glass Filled PEEK.

PEEK is a great source for CNC machined parts when harsh environment applications are necessary. PEEK is a very hard plastic and will not easily be bent or flexed. This is good for CNC machining in that surface finishes clean up extremely well with the proper tooling. Additionally, PEEK does not vary dimensionally (grow or shrink) after machining unless a high temperature is applied during the CNC machining process.